What is the maximum load an end clamp can bear?

As a supplier of End Clamps, I often get asked about the maximum load these clamps can bear. This is a crucial question, especially for those in the solar installation industry, where end clamps play a vital role in securing solar panels and ensuring the stability of the entire structure. In this blog post, I'll delve into the factors that determine the maximum load of an end clamp, how to calculate it, and why it matters in real - world applications.

Factors Affecting the Maximum Load of an End Clamp

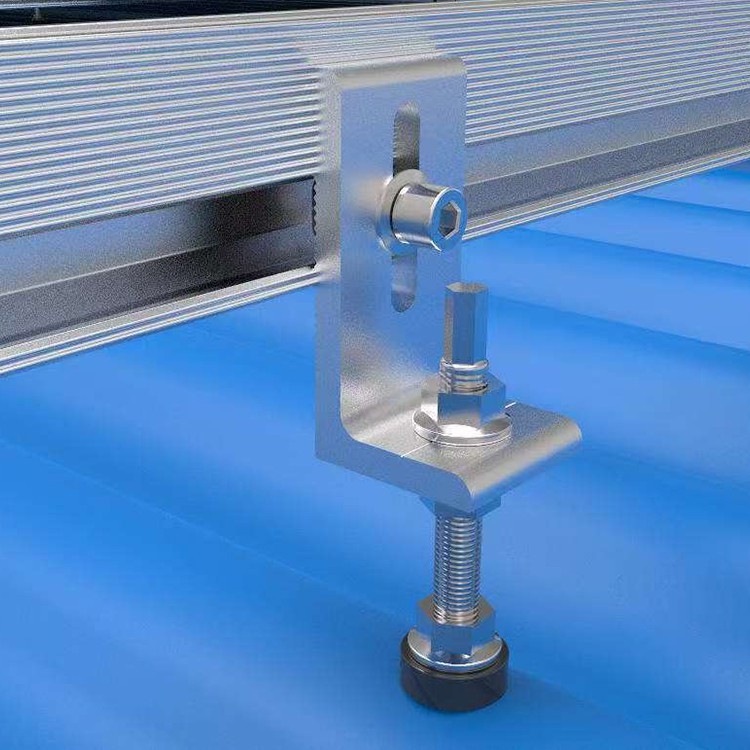

The maximum load an end clamp can bear is influenced by several key factors. First and foremost is the material of the clamp. End clamps are typically made from materials like aluminum or stainless steel. Aluminum is lightweight, corrosion - resistant, and has good strength - to - weight ratio. Stainless steel, on the other hand, offers even higher strength and better resistance to harsh environmental conditions. The inherent properties of these materials set the baseline for the load - bearing capacity of the clamp.

The design of the end clamp also plays a significant role. A well - designed end clamp will distribute the load evenly across its structure. For example, clamps with wider contact surfaces with the solar panel frame can better transfer the load, reducing stress concentration points. Some end clamps are designed with multiple gripping points or teeth, which can increase the friction between the clamp and the frame, thereby enhancing the load - bearing capacity.

Another important factor is the installation method. If the end clamp is not installed correctly, it can significantly reduce its load - bearing capacity. For instance, if the bolts are not tightened to the recommended torque, the clamp may not grip the frame firmly enough, leading to slippage under load. Similarly, incorrect alignment of the clamp on the frame can cause uneven loading and premature failure.

Environmental conditions also impact the maximum load an end clamp can bear. In areas with high wind speeds, the clamps need to withstand the uplift and lateral forces exerted by the wind on the solar panels. Extreme temperatures can also affect the material properties of the clamp. For example, in very cold temperatures, some materials may become more brittle, reducing their ability to withstand loads.

Calculating the Maximum Load

Calculating the maximum load of an end clamp is a complex process that requires a combination of engineering knowledge and testing. Manufacturers typically conduct extensive laboratory tests to determine the load - bearing capacity of their end clamps. These tests simulate real - world conditions, including different types of loads (such as static, dynamic, and cyclic loads) and environmental factors.

One common method of testing is the static load test. In this test, a gradually increasing load is applied to the end clamp until it fails. The maximum load at which the clamp fails is recorded as its ultimate load - bearing capacity. However, in real - world applications, a safety factor is usually applied to this value. A typical safety factor can range from 1.5 to 3, depending on the application and the level of risk tolerance.

For example, if the ultimate load - bearing capacity of an end clamp is determined to be 1000 N through laboratory testing, and a safety factor of 2 is applied, the maximum allowable load in a real - world installation would be 500 N.

In addition to laboratory testing, engineers may also use finite element analysis (FEA) to predict the load - bearing capacity of end clamps. FEA is a computer - based simulation technique that models the behavior of the clamp under different loads. By inputting the material properties, design parameters, and boundary conditions, engineers can obtain detailed information about the stress distribution and deformation of the clamp, which helps in optimizing the design and estimating the maximum load.

Importance in Real - World Applications

In the solar installation industry, understanding the maximum load an end clamp can bear is of utmost importance. Solar panels are often installed in large arrays, and each panel is held in place by multiple end clamps. If an end clamp fails under load, it can lead to the displacement or even detachment of a solar panel, which not only reduces the energy output of the system but also poses a safety hazard.

For example, in a solar farm located in a coastal area with high wind speeds, the end clamps need to be able to withstand the strong winds. If the maximum load of the end clamps is underestimated, there is a risk of the panels being blown off during a storm. This can result in significant financial losses due to damage to the panels and the cost of repair and replacement.

Moreover, in regions with seismic activity, end clamps need to be able to withstand the dynamic loads caused by earthquakes. A well - designed and properly installed end clamp with an appropriate maximum load capacity can help ensure the structural integrity of the solar panel system during an earthquake.

Related Products and Their Role

When it comes to solar panel installations, end clamps are not the only components that matter. Other accessories like Straight Connector and L Leg also play important roles.

Straight connectors are used to connect different sections of the solar panel mounting rails. They ensure a secure and stable connection, which is essential for distributing the loads evenly across the entire mounting structure. A good straight connector should have sufficient strength and corrosion resistance to withstand the environmental conditions and the loads transferred from the panels and end clamps.

L legs are used to support the solar panel mounting rails and provide a stable base for the entire system. They need to be able to bear the weight of the panels, the mounting structure, and any additional loads such as wind and snow. The load - bearing capacity of the L legs also needs to be carefully considered in conjunction with the end clamps to ensure the overall stability of the solar panel installation.

Conclusion

In conclusion, the maximum load an end clamp can bear is determined by a variety of factors, including the material, design, installation method, and environmental conditions. Calculating this maximum load requires a combination of laboratory testing and engineering analysis. Understanding the maximum load is crucial for ensuring the safety and reliability of solar panel installations.

If you are in the market for high - quality End Clamps or other solar accessories, I encourage you to reach out to us. We have a wide range of products that are designed and tested to meet the highest standards of quality and performance. Whether you are working on a small residential solar project or a large - scale commercial solar farm, we can provide you with the right solutions. Contact us today to start a procurement discussion and find out how our products can meet your specific needs.

References

- ASCE 7 - 16, Minimum Design Loads and Associated Criteria for Buildings and Other Structures.

- IEC 61215, Crystalline silicon terrestrial photovoltaic (PV) modules - Design qualification and type approval.

- Manufacturer's technical documentation for end clamps, straight connectors, and L legs.